Odor Measurements: A Keen Sense of Smell for Clean Air

Author: Thorsten Rienth

DEKRA now offers professional odor measurements throughout Germany. In these measurements, the nose plays a key part in the objective evaluation of odors.

What doesn't bother one person may cause discomfort in another. “Similar to tastes, smells are subjective,” explains Stephan Mahlberg, specialist responsible for air pollution control at DEKRA. Although not always directly harmful to health, substances from agriculture, the chemical industry, and other odor-intensive production sectors can affect well-being or cause complaints from neighbors. In accordance with German legal guidelines (e.g., Federal Immission Control Act - BImSchG, Technical Instructions on Air Quality Control – TA Luft, or GIRL), operators must therefore have the type and extent of odors assessed objectively and legally by an

accredited measurement agency such as DEKRA.

The human nose and high-tech technology complement each other perfectly in odor measurements

At the start of the year, DEKRA acquired the Braunschweiger Umwelt-Biotechnologie GmbH (BUB) in Germany. With this acquisition, the expert organization has closed a regional gap in the network of DEKRA environmental measuring stations in northern Germany. For customers, this means that DEKRA now offers a comprehensive range of air pollution control services throughout Germany.

While this may sound straightforward, it is anything but simple in practice, as expert Mahlberg explains. "Providing professional odor measurements on a broad scale is not that easy. Evaluating odors using physical-chemical measurement methods is either very complex or not possible at all." At the molecular level, odors are highly complex. For example, the exhaust air from a pigsty contains a complex mixture of several thousand individual components. A genuine molecular orchestra that is almost impossible to analyze chemically in its entirety.

Ironically, it is the human nose, such a subjective organ of smell, that plays a key role in the objective evaluation of odors. Within milliseconds, the olfactory center decides whether an odor is perceived as pleasant, neutral, or unpleasant.

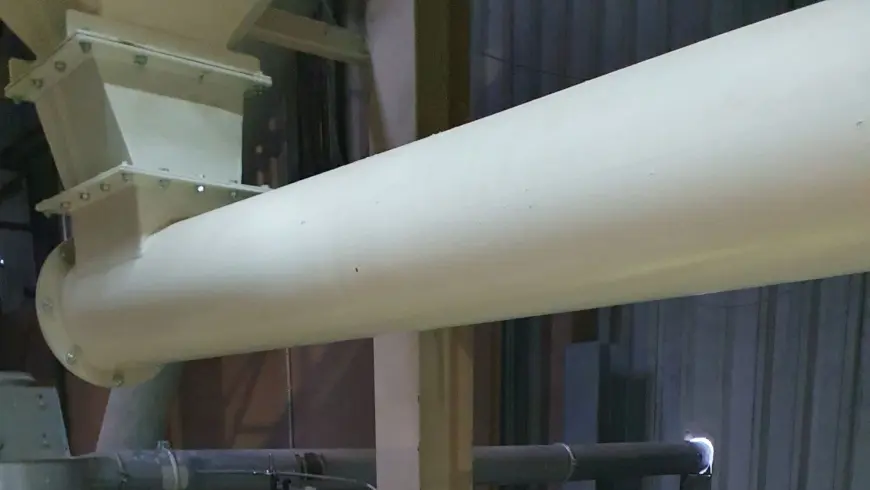

Equally important is the testing equipment, known as an olfactometer. It mixes sample air with odorless air in specified proportions. The air is then inhaled by a specially trained panel of testers using the olfactometer. Each tester presses a button as soon as they detect the odor. With the necessary expertise, the odor concentration can be calculated from the averaged responses of at least four testers—and thus objectively determine whether the odor is still below or already above the threshold for nuisance. The question that it all comes down to is: Do the testers perceive the odor? And if so, starting at what concentration?

Odors dissipate quickly – which is why excellent organization is essential

Another crucial factor in professional odor measurement is that the panel of testers, the olfactometer, and the sampling location cannot be too far apart geographically. “Since odorous substances can be chemically unstable or react with other substances, the samples must be evaluated within six hours,” explains DEKRA expert Mahlberg.

The normative requirements pose challenges for project planning. This means that the following aspects must be taken into account for scheduling: Sampling on site at the customer's premises takes about two hours and consists of at least three individual samples. Each sample is then smelled in three separate rounds, and an average value is calculated. The analysis of an odor sample by the panel of testers and the test supervisor takes about 30 minutes. This results in two options for project planning and the design of sampling and evaluation: Either the sample is quickly transported to the panel of testers and the olfactometer. Alternatively, the panel and olfactometer are used near the sampling location in an odor-neutral room.

However, the uncertainties do not end there. “Before the actual test, the examiners must first be ‘calibrated’,” says Mahlberg. This is where n-butanol comes into play. “The substance is used in odor threshold measurements as an internationally standardized reference substance to determine people’s sensitivity to odors objectively and comparably,” explains Mahlberg. “Its odor threshold is well known scientifically, and the substance varies little in its perception.” To this end, it is presented in air in various, precisely defined concentrations and tested to determine at what point the tester reliably perceives the odor.

To be on the safe side, a fifth substitute tester is always present during the measurements. “If someone has a cold, for example, they are not allowed to be included in the tester panel on that day due to the strict regulations.”

Broad DEKRA portfolio for professional odor measurements

When industrial or commercial enterprises are required to carry out regular emission measurements, in practice it is rarely just a matter of odors. Chemical hazardous substances, particles, and dust pollution must also be recorded and evaluated. "This plays right into our hands as an expert organization: we provide our customers with complete solutions for air pollution control from a single source." In the context of air pollution control, DEKRA is approved for professional measurements of emissions and immissions in all known substance groups – particles, gaseous substances such as nitrogen oxides, and substances with high sampling requirements (dioxins, asbestos) as well as odors.